How does Amazon work? Take a look inside one of the retail giant’s robot-powered Australian fulfilment centres

Robots, conveyor belts and video games — the inside of one of Amazon’s Australian warehouses may not be exactly what you think. Here’s what goes down when a customer buys an item online.

Seconds after an Australian customer clicks buy on the website Amazon, a notification is sent to the e-commerce giant’s fulfilment centre in Sydney’s far west.

One of six fulfilment centres currently operating nationwide, the 200,000 square metre warehouse in Kemps Creek is powered by robotics and stacked with millions of small to medium products including handwash, acrylic paint and cartons of soy milk.

The vast inventory of consumer items is stored on yellow shelves kept side-by-side, like a high visibility library, inside fenced-off areas over three floors of the warehouse.

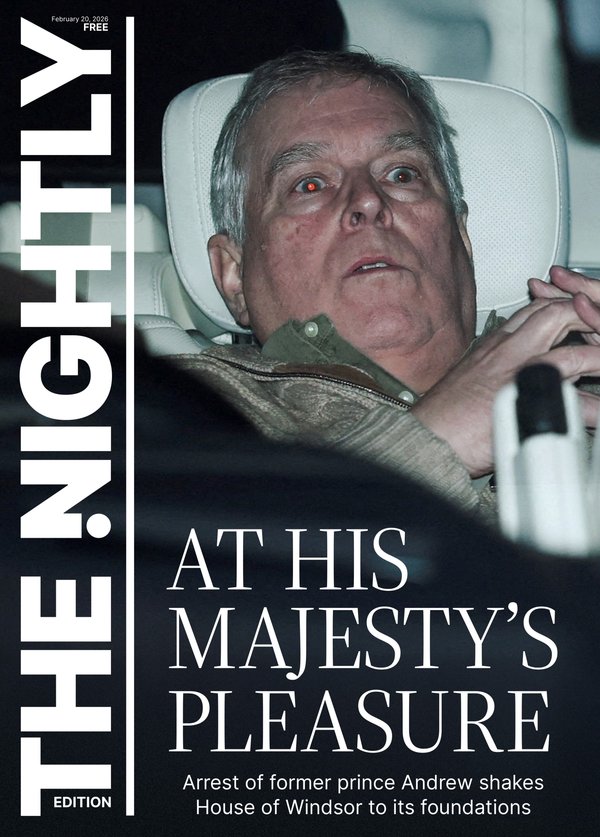

Sign up to The Nightly's newsletters.

Get the first look at the digital newspaper, curated daily stories and breaking headlines delivered to your inbox.

By continuing you agree to our Terms and Privacy Policy.About 5km of safety fencing has been installed to create the robotics fields.

Only specialist staff are allowed inside due to the risk of collision with the robots that store and fetch the products.

When they enter they must wear vests that repel the robots, which are guided by QR codes and tracks etched into the linoleum floor.

The robots are flat, blue and square. They whir as they slot beneath shelves of products and take them to the designated collector.

A controller watches a screen showing the movements of the robots, represented by orange squares, amongst a grid of blue squares that represent the product shelves. It almost looks like the classic arcade game of Pac-Man.

Amazon, founded by American billionaire Jeff Bezos, has made no secret it has ambitions to expand in Australia and has invested billions in its local operations.

The world’s sixth most valuable publicly listed company has plans to open another three fulfilment centres, including two in the western Sydney suburb of Horsley Park at a cost of $490 million.

Another fulfilment centre is under construction in the Melbourne suburb of Craigieburn. At a planned 209,000sqm, it will be Amazon’s largest in Australia.

Amazon Australia Site Leader Sherif Zaki said the retail behemoth believed how it did business was the future of retail in Australia.

“We know our customers want things quickly and our automation at facilities like this one allows us to do just that,” he said.

“We know that at scale we can continue to deliver for our customers.”

At the Kemps Creek fulfilment centre, products as diverse as packs of red nutrient water and Taylor Swift CDs are transported throughout the warehouse on 14km of conveyancing equipment.

When a customer purchases an item online, a notification is sent to an Amazon worker called an associate.

A robot brings the shelf to the designated associate where a light shines on the freshly purchased product, a measure intended to increase worker speeds.

Amazon has even turned the process into a video game called Mission Masters, with a screen broadcasting each worker’s stats as they compete against each other.

The associate grabs the product and puts it in a yellow container, called a tote, that is ferried along one of the conveyor belts that rumble throughout the warehouse to a packer on the ground floor.

The song Rolling in The Deep by English singer Adele plays as Maria Visser, a packer, prepares packages for shipping underneath artificial lights.

Ms Visser said on average she packaged about 100 parcels an hour, meaning she completes about 1000 each 10-hour shift.

“The product comes on the conveyor belt [and] the system already knows how many items are supposed to be in that tote [container],” she said.

“When I scan an item [the machine] will tell me what size box the item will go in.”

Ms Visser then prints a shipping label and slaps it on the package before putting it on a different conveyor belt.

The e-commerce giant, which currently employs 7000 people in Australia, is currently attempting to recruit an additional 1400 workers ahead of the company’s retail holiday Prime Day.