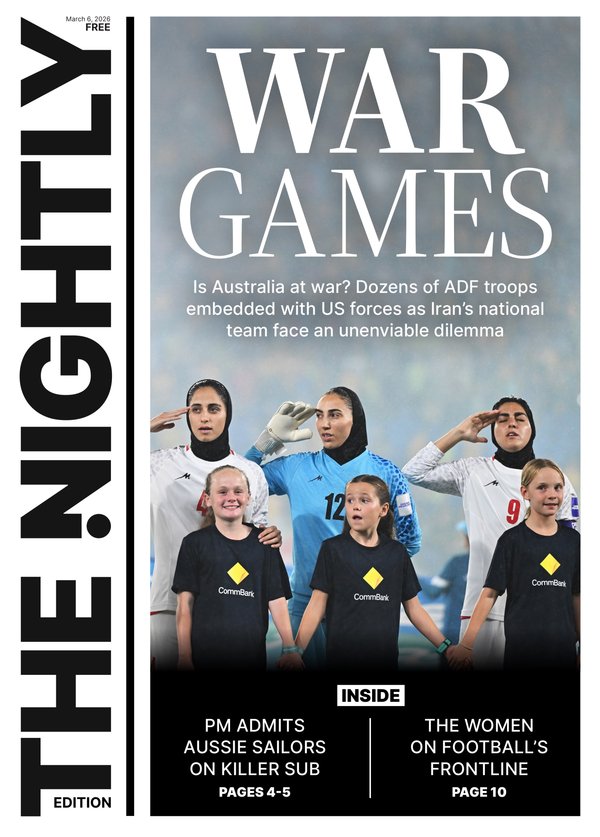

The Nightly On ... Tomorrow: Grubs up! What a world heading towards 10 billion people will eat in the future

Feeding 10 billion people by 2050 won’t be easy, but growing meat and feasting on insects are some of the ways to get us there.

What will sir have tonight? Charcoal-grilled cultivated dodo with a side serve of crispy fried crickets and salad of genetically modified seaweed from our vertical farm is a popular dish.

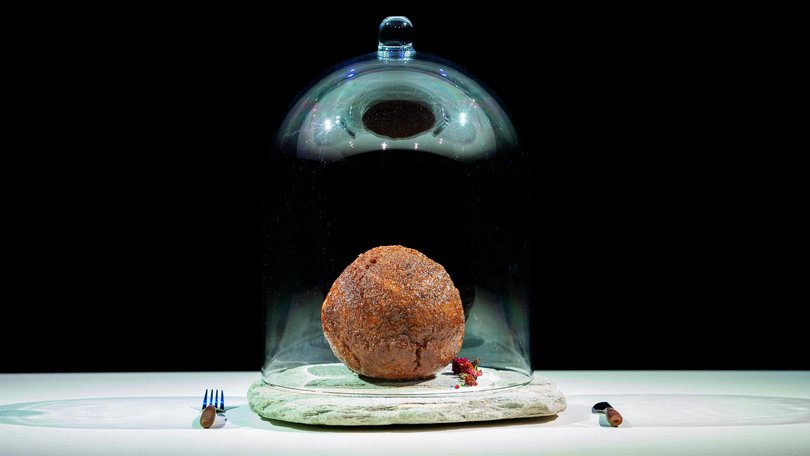

Or what about the braised mammoth meatballs with garlic-fried larvae?

Sounds far-fetched, like something out of Jurassic Park, but those tasty meatballs exist.

Sign up to The Nightly's newsletters.

Get the first look at the digital newspaper, curated daily stories and breaking headlines delivered to your inbox.

By continuing you agree to our Terms and Privacy Policy.Australian cultured or lab-grown meat company Vow grabbed headlines in 2023 with its mammoth meatball made from lamb, mammoth and African elephant DNA.

Described by Forbes magazine as the “spaceship of the cultured meat industry”, Vow was founded in 2019 by former chef George Peppou and entrepreneur Tim Noakesmith with the aim of using animal cells to define the future of food. The company currently sells its cultivated quail parfait and foie gras to Singapore and Hong Kong fine diners while awaiting regulatory approval for Australia.

Cultured meat is in its infancy, but lab-grown protein alongside insects, AI-driven robot farms and vertical urban greenhouses are on the menu as the world grapples with how to feed 10 billion people by 2050. That demands an increase in food production of about 70 per cent.

Simon Eassom from independent think tank Food Frontier says we need to reduce reliance on animal agriculture, which produces between a quarter and a third of all global greenhouse emissions. As temperatures rise, we need more water to grow fewer plants.

Professor Johannes le Coutre, a food and health expert from the University of NSW, believes we will still eat meat in 25 years but far less of it will come from livestock.

“There are simply not enough cows on this planet to meet projected food production demands,” he says, “and we can’t ignore the looming environmental challenges posed by the agriculture and food industry.”

The alt-protein sector is tipped to grow into a $65 billion market by 2034.

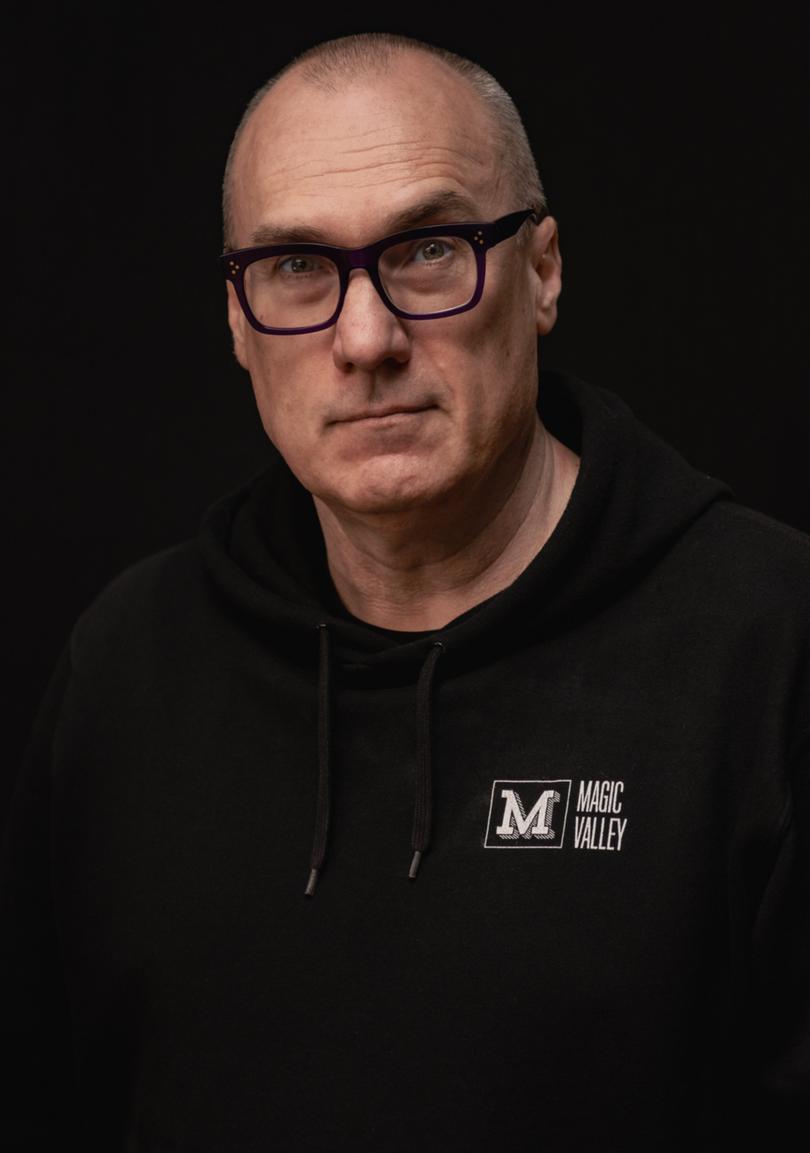

In February, Melbourne-based cultivated meat makers Magic Valley received $100,000 in matched funding from the Federal Government to shift from research to commercial production.

Launched in 2020, Magic Valley specialises in lab-grown pork and lamb made by taking a small sample of skin cells from a living animal, which are grown in a bioreactor before being harvested and turned into meat products. The cells’ growth is unlimited, meaning this process can be repeated time and again.

Magic Valley’s head of research and development Professor Andrew Laslett says it is “not too hard” to replicate the taste and texture of traditionally farmed meat “because what we’re growing are actual animal cells”.

It also removes the emotional baggage of animal slaughter.

Magic Valley, which hopes to commercially launch its first products by next year, says the process reduces emissions by 92 per cent, land use by 95 per cent and water use by 78 per cent compared to conventional farming.

MAGGOT BURGERS

Expect to see crickets, cockroaches and other insects on your plate, if they’re not already. More than two billion people across 130 countries eat insects, which are a source of high-quality protein, fats, iron, zinc and vitamins.

“They actually taste quite good,” says Dr Regine Stockmann, principal scientist at CSIRO. “You wouldn’t know unless someone tells you.”

But what about maggots? Specifically, black soldier fly larvae that transform waste into nutrient-rich bio-fertiliser or frass. Around 30 per cent of the world’s food production goes to waste, costing the global economy approximately $940b each year, so anything that reduces waste is good news.

A 2020 University of Queensland study found that black soldier fly larvae contain more zinc and iron than lean meat and their calcium content is higher than milk. They have the potential to replace meat in burger patties and sausages.

LUPIN YOU IN

Dr Rose Roche is the head of Ag2050, a CSIRO-funded program looking at how to make Australian farming systems profitable, sustainable and productive. Part of that picture is more protein-rich legumes, including black beans, chickpeas, lupins and lentils.

Australia grows more than 85 per cent of the world’s lupins, which use minimal water to grow and put nitrogen back into the ground.

“Legumes are really good for human nutrition,” Roche says, “but they also reduce your reliance on synthetic fertilisers, which might be more expensive in the future.”

GOT MILK?

Melbourne-based Eden Brew claims its precision-fermented milk “tastes like milk” but “without the downsides”.

The company developed what it calls a world-first animal-free casein micelle, the building block of cow milk responsible for 80 per cent of dairy protein. Less than 10 litres of water is used in making a litre of Eden Brew’s product compared to 1000 litres for cow’s milk and 6000 litres for almond milk.

The sustainable mission raised $25 million in funding in 2023 and has attracted investment from Australian musicians Bernard Fanning and Angus Stone, music promoter Paul Piticco and Paralympian Dylan Alcott, plus the Victorian Government.

GOING SIDEWAYS

Why farm on flat soil when you can grow crops vertically in stacked layers of environmentally controlled agriculture?

Vertical farms such as the Gold Coast-based Stacked Farm and Eden Towers in Western Australia are developing what they describe as the “farms of the future”, producing herbs at the same price or cheaper than traditional farms, with a longer shelf life and smaller environmental footprint.

Eden Towers claims to use 98 per cent less water and a tenth of the space while producing close to zero emissions.

Vertical farms use AI and robots to automate production from seeding to harvesting.

Stacked Farm recently announced plans to build a 10,000sqm “automated veggie patch” in Melbourne to produce 3.4 million kilograms of greens each year with just 15 staff.

RISE OF THE ROBOTS

Traditional farmers are also turning to AI. Queensland-based SwarmFarm Robotics has created a spot-spray machine which reduces chemical usage and costs. The machine is armed with software to help make data-driven decisions but is simple enough to be fixed by farmers.

The company has deployed more than 130 autonomous robots, or SwarmBots, to farm more than two million hectares and reduce pesticide usage by around five million tonnes.

“The beauty of a robot is that it can go all hours of the day,” SwarmFarm spokesperson Tom Holcombe says. “It’s not limited by when someone’s awake, not on holidays or the fact Friday afternoon is rolling around.”

THE BIG, BIG PICTURE

Theoretically, we make enough tucker to feed the planet. Reducing waste at all stages of the supply chain should be a top priority but alone won’t solve food security issues, which range from wars and pandemics to economic inequity.

Professor le Coutre says reducing food wastage, alleviating poverty and innovating to find more sustainable sources of protein (maybe not mammoth meatballs) are key to solving the world’s food security crisis.

“If we can achieve all three on a global scale, we’ll have the right recipe to a more sustainable food system,” he says.