THE NEW YORK TIMES: Norway’s hedged bet on Europe’s energy future, a garbage disposal for emissions

THE NEW YORK TIMES: Oslo wants to parlay the skills of the petroleum industry and its favourable geology into a kind of garbage disposal service for emissions from heavy industry.

On the edge of a fjord on Norway’s rocky west coast is a massive, almost sculptural structure that represents a multibillion-dollar bet on the economic future of energy in Northern Europe.

The tanks at Oygarden, near the port city of Bergen, hold thousands of tons of liquid carbon dioxide extracted from the exhaust produced by a cement plant in southern Norway.

The carbon dioxide, which is transported by ship to the tanks, will soon be piped about 70 miles offshore and down an 8,500-foot well in the North Sea, where it will be locked away in the spongy rock, the project’s developers say.

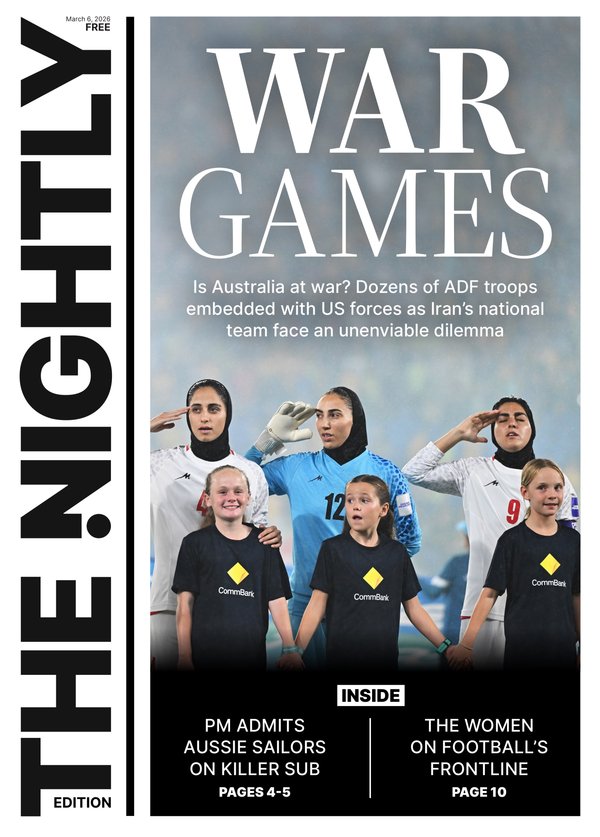

Sign up to The Nightly's newsletters.

Get the first look at the digital newspaper, curated daily stories and breaking headlines delivered to your inbox.

By continuing you agree to our Terms and Privacy Policy.Norway has long been Europe’s leading producer of oil and natural gas. Now, with an eye to a future when earnings from those resources may decline, Oslo wants to parlay the skills of the petroleum industry and its favourable geology into a kind of garbage disposal service for emissions from heavy industry.

“What we can offer is a flexible solution,” said Aksel Plener, the operations manager of the project, which is known as Northern Lights. “So long as you have a jetty and CO2 tanks, we can go now and pick it up for you.”

Northern Lights is being closely watched as a potential model for other efforts using a process known as carbon capture and storage to clean up industries such as cement and fertiliser that pump out huge amounts of carbon dioxide.

These businesses are facing a tight squeeze in Europe because of taxes on emissions and other environmental regulation.

Carbon capture could also prove to be a new line of business for oil and gas giants. Plener, a former operations manager at a Norwegian oil field called Knarr for Shell, Europe’s largest energy company and one of the owners of Northern Lights.

Shell’s partners are two other giants, Equinor of Norway and TotalEnergies of France.

Long considered a potentially important tool for reducing emissions, carbon capture has been slower to gain traction than some analysts had expected. High costs and environmental concerns have been obstacles.

Northern Lights is among the most advanced of the latest generation of strategies that are profitable, at least according to some metrics.

“It’s the first of what we expect many more projects to look like,” said Mhairidh Evans, a vice president and global head of carbon capture research at Wood Mackenzie, an energy consulting firm.

There are many carbon capture plans on the drawing board, Evans said, and those that receive a green light could make money.

“Are they as profitable as producing oil or gas? Probably not,” she said. “But they’re more stable.”

In a sign of the increasing acceptance of carbon capture, 20 financial institutions agreed to lend about 8 billion pounds in debt for two carbon capture projects in northeast England, including a natural-gas-fired power station called Net Zero Teesside Power. The French bank Société Générale arranged and advised on the financing.

The deal in Britain is “an important milestone,” said Carl Greenfield, a carbon capture analyst at the International Energy Agency.

In Norway, the energy giants aim to gain scale and bring down costs by creating a regional service, signing up polluters around the North Sea.

Arrangements vary, but Wood Mackenzie estimates that customers will pay a fee of $50 to $60 a metric ton to have their carbon dioxide taken off their hands. That price would be less than Europe’s tax on emissions of around 70 euros a ton, but polluters would also face other costs.

Along with building the terminal at Oygarden, Northern Lights has ordered specialised tankers to be constructed in China to haul the carbon dioxide. Two have already made the trip over, with two more expected.

More than 400 feet long, the ships have a cylindrical rotor sail to trim fuel consumption and bristle with tanks and pipes designed to handle the cargo.

Hroar Skofteby, the captain of one of these vessels, the Northern Pathfinder, said it would eventually ferry carbon dioxide between power plants operated by Orsted, the Danish renewables giant, near Copenhagen and the storage terminal at Oygarden.

Northern Lights also has agreements to take carbon dioxide from a fertiliser plant in the Netherlands and a heating and generating site in Sweden.

To encourage participation, the Norwegian government is putting up about 34 billion krone, or around $3.3 billion, to cover about two-thirds of the costs of building the facilities for Northern Lights and the first 10 years of operations.

Other governments, including Sweden’s and the European Union’s, are also contributing funds.

“The main objective of the project is to kick-start a market for CCS in Europe,” said Alexander Engh, deputy director general of Norway’s energy ministry. “The best way to do that was to force or incentivise the companies to go out and develop that market.”

Oslo is trying to make a virtue of the legacy of the oil industry and gain a lead in Europe in what the government described in a paper as “socioeconomically profitable storage of CO2.”

According to government estimates, the rocks under Norway’s seabed have the capacity to store as much as 80 billion metric tons of carbon dioxide, or 1,600 years of Norway’s emissions at current levels, in depleted natural gas fields and other porous rocks.

“The stars have aligned for Norway,” said Hasan Muslemani, head of carbon management research at the Oxford Institute for Energy Studies.

The government is making Northern Lights worthwhile for its participants. Wood Mackenzie, for instance, estimates that Shell and the other owners could see profits of around 10%.

But costs remain high, and the project is feasible only because of the government backing.

Because carbon capture is a fledgling industry, it “still requires subsidies or support from governments,” said Bernhard Koudelka, vice president for carbon capture at Shell.

Evans, the analyst at Wood Mackenzie, estimates that transporting and storing the carbon dioxide costs around $75 a ton. Sequestering the gas, though, can cost up to $400 a ton, depending on the type of plant.

Such expenses mean that makers of products such as cement, which ordinarily costs about 130 euros a ton, need to find a way to charge a premium for being greener.

Heidelberg Materials, a German company that makes construction products, operates a cement plant at Brevik that is an anchor customer of Northern Lights. Executives estimate the price of net low carbon cement made there will be about three times the price of ordinary cement, even though it will be physically identical.

The product, called Evozero, “provides a very significant value,” said Christoph Beumelburg, Heidelberg’s communications and investor relations director, adding that its order book is sold out for the year.

This article originally appeared in The New York Times.

© 2025 The New York Times Company

Originally published on The New York Times